| Rolling Stock Cables | |||||||||||||||

![]() FIREROL FRL-SW-05M-OS-AS+, FRL-SW-1M-OS-AS+

FIREROL FRL-SW-05M-OS-AS+, FRL-SW-1M-OS-AS+

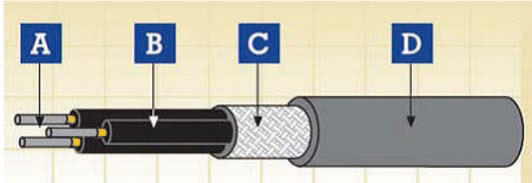

A. Conductor B. Insulation C. Screen D. Sheath

Application

-Used as power and control cable for protected installations inside and outside of rail and transport vehicles, where handling and installation cost are an important factor.

-Used in control, auxillary and main circuit wiring such as cable harnesses, switchboards and control panels, driver desks etc.

Construction

Conductor

Flexible tinned annealed copper wires, stranded as per HD 383 (IEC 60228) class 5

Insulation

LSZH elastomeric compound as defined in EN 50264-1 (EI 101 to EI 105)

Overal screen

Tinned annealed copper wires

Outer sheath

LSZH elastomeric compound as defined in EN 50264-1 (EM 101 to EM 104)

Electrical & Mechanical Properties

| Nominal Voltage | 300/500 V or 0.6/1 kV |

| Maximum Conductor Temperature | +90 deg (fixed installation) |

| Minimum Permissible Ambient Temperature | -25/-40 deg (fixed installation) |

| Bending Radius | 10 x Overall Diameter |

Chemical & Environmental Properties

| EN 60684-2 | No fluorine |

| EN 50305; EN 60811-2-1 | Resistance to oil & fuel |

| EN 50305 | Resistance to ozone |

Fire Performance for rolling stock application

| EN 50306-2 | Hazard levels HL1, HL2/HL3, HL4 |

| DIN 5510-2 | Protection level 1/2/3/4 |

| BS 6853 | Interior use 1a, 1b, II; Exterior use 1a, 1b, II |

| NF F 16-101 | FO |

Fire Performance in general

| EN 50265-2-1; IEC 60332-1-2; NF C 32-070 2.1 (C2) | Vertical flame propogation for a single insulated wire or cable |

| EN 50266-2-4 + EN 50305; IEC 60332-3-24; NF C 32-070 2.2 (C1); VDE 0472 Teil 804 |

Vertical flame spread of vertically mounted bunched wires or cables |

| EN 50268-2; IEC 61034-2; NF C 32-073 ; NF C 20-902; NF F 16 101; VDE 0472 Teil 816 |

Low Smoke Emission |

| EN 50267-2-1; IEC 60754-1; NF C 32-074;NF C 20-454; VDE 0472 Teil 815 | Halogen Free |

| EN 50267-2-2/3; IEC 60754-2; NF C 32-074;NF C 20-453; VDE 0472 Teil 813 | Low Corrosivity (Acidity & Conductivity) |

| EN 50305; NFX 70-100; NFF 63808; TM1-04; BS6853 | Low Toxicity |

| NFF 16101; NFF 63808; BS6853 | Smoke index |

| IEC60331-21 | The circuit integrity test under fire of cables rated 0.6/1.0kV and below |

FRL-SW-05M-OS-AS+ 300/500 V

| Number And Nominal Cross-Sectional Area(a) |

Conductor Diameter (b) |

Min. Mean Thickness of Insulation |

Diameter of Core(b) | Min Wire Diameter of Screen |

Min. Mean Thickness of Sheath |

Overall Diameter |

Weight | Maximum Conductor Resistance | Insulation Resistance | |||

| EI 105 | EI 101-EI 104 | |||||||||||

| Min | Max | Min | Max | 20°C | 20°C | 20°C | ||||||

| n x mm2 | mm | mm | mm | mm | mm | mm | mm | mm | kg/km | Ω/km | MΩ x km | MΩ x km |

| 2x1 | 1.25 | 0.6 | 2.7 | 3.1 | 0.16 | 1.4 | 8.3 | 9.8 | 129 | 20.0 | 140 | 70 |

| 4x1 | 0.6 | 2.7 | 3.1 | 0.16 | 1.4 | 9.2 | 10.9 | 188 | 20.0 | 140 | 70 | |

| 7x1 | 0.6 | 2.7 | 3.1 | 0.16 | 1.4 | 10.6 | 12.5 | 275 | 20.0 | 140 | 70 | |

| 9x1 | 0.6 | 2.7 | 3.1 | 0.21 | 1.4 | 12.7 | 14.9 | 360 | 20.0 | 140 | 70 | |

| 12x1 | 0.6 | 2.7 | 3.1 | 0.21 | 1.4 | 13.5 | 15.9 | 445 | 20.0 | 140 | 70 | |

| 19x1 | 0.6 | 2.7 | 3.1 | 0.26 | 1.5 | 15.9 | 18.7 | 665 | 20.0 | 140 | 70 | |

| 24x1 | 0.6 | 2.7 | 3.1 | 0.26 | 1.6 | 18.3 | 21.5 | 832 | 20.0 | 140 | 70 | |

| 32x1 | 0.6 | 2.7 | 3.1 | 0.26 | 1.6 | 19.9 | 23.4 | 1043 | 20.0 | 140 | 70 | |

| 37x1 | 0.6 | 2.7 | 3.1 | 0.26 | 1.7 | 20.9 | 24.5 | 1181 | 20.0 | 140 | 70 | |

| 40x1 | 0.6 | 2.7 | 3.1 | 0.26 | 1.7 | 21.6 | 25.4 | 1263 | 20.0 | 140 | 70 | |

| 4x1.5 | 1.5 | 0.7 | 3.0 | 3.5 | 0.16 | 1.4 | 10.3 | 12.1 | 244 | 13.7 | 120 | 60 |

| 7x1.5 | 0.7 | 3.0 | 3.5 | 0.21 | 1.4 | 12.1 | 14.3 | 380 | 13.7 | 120 | 60 | |

| 9x1.5 | 0.7 | 3.0 | 3.5 | 0.21 | 1.4 | 14.3 | 16.8 | 476 | 13.7 | 120 | 60 | |

| 12x1.5 | 0.7 | 3.0 | 3.5 | 0.21 | 1.5 | 16.0 | 18.8 | 604 | 13.7 | 120 | 60 | |

| 19x1.5 | 0.7 | 3.0 | 3.5 | 0.26 | 1.5 | 18.0 | 21.1 | 895 | 13.7 | 120 | 60 | |

| 24x1.5 | 0.7 | 3.0 | 3.5 | 0.26 | 1.6 | 20.9 | 24.5 | 1120 | 13.7 | 120 | 60 | |

| 32x1.5 | 0.7 | 3.0 | 3.5 | 0.26 | 1.7 | 22.9 | 26.9 | 1430 | 13.7 | 120 | 60 | |

| 37x1.5 | 0.7 | 3.0 | 3.5 | 0.26 | 1.7 | 23.8 | 27.9 | 1610 | 13.7 | 120 | 60 | |

| 4x2.5 | 1.95 | 0.8 | 3.6 | 4.2 | 0.21 | 1.4 | 12.0 | 14.2 | 330 | 8.21 | 90 | 45 |

| 7x2.5 | 0.8 | 3.6 | 4.2 | 0.21 | 1.4 | 13.9 | 16.4 | 500 | 8.21 | 90 | 45 | |

| 9x2.5 | 0.8 | 3.6 | 4.2 | 0.26 | 1.5 | 17.0 | 20.0 | 670 | 8.21 | 90 | 45 | |

| 12x2.5 | 0.8 | 3.6 | 4.2 | 0.26 | 1.5 | 18.2 | 21.4 | 830 | 8.21 | 90 | 45 | |

| 19x2.5 | 0.8 | 3.6 | 4.2 | 0.26 | 1.6 | 21.3 | 24.9 | 1200 | 8.21 | 90 | 45 | |

| 24x2.5 | 0.8 | 3.6 | 4.2 | 0.26 | 1.8 | 24.9 | 28.9 | 1560 | 8.21 | 90 | 45 | |

(a)= One earth conductor (green/yellow) can be included upon request

(b)= For information,indicative only

FRL-SW-1M-OS-AS+ 0.6/1 kV

Number |

Conductor Diameter (b) |

Min. Mean |

Diameter of Core(b) |

Min Wire Diameter of Screen |

Min. Mean Thickness of Sheath |

Overall Diameter |

Weight | Maximum Conductor Resistance | Insulation Resistance | |||

| EI 105 | EI 101-EI 104 | |||||||||||

| Min | Max | Min | Max | 20°C | 20°C | 20°C | ||||||

| mm2 | mm | mm | mm | mm | mm | mm | mm | mm | kg/km | Ω/km | MΩ x km | MΩ x km |

| TWO CORES | ||||||||||||

| 1.5 | 1.5 | 0.8 | 3.3 | 3.8 | 0.16 | 1.4 | 9.5 | 11.2 | 166 | 13.7 | 150 | 75 |

| 2.5 | 1.95 | 0.8 | 3.7 | 4.2 | 0.16 | 1.4 | 10.4 | 12.2 | 207 | 8.21 | 130 | 65 |

| 4 | 2.5 | 0.8 | 4.2 | 4.9 | 0.21 | 1.4 | 11.7 | 13.7 | 273 | 5.09 | 110 | 55 |

| 6 | 3.0 | 0.9 | 4.9 | 5.7 | 0.21 | 1.4 | 13.1 | 15.4 | 351 | 3.39 | 90 | 45 |

| 10 | 3.9 | 1.1 | 6.1 | 7.1 | 0.21 | 1.5 | 15.7 | 18.5 | 515 | 1.95 | 85 | 45 |

| 16 | 5.0 | 1.1 | 7.5 | 8.8 | 0.26 | 1.5 | 18.1 | 21.2 | 710 | 1.24 | 70 | 35 |

| 25 | 6.4 | 1.3 | 8.9 | 10.3 | 0.26 | 1.7 | 21.8 | 25.6 | 1035 | 0.795 | 65 | 35 |

| 35 | 7.7 | 1.3 | 10.5 | 11.8 | 0.31 | 1.8 | 24.6 | 28.9 | 1339 | 0.565 | 60 | 30 |

| 50 | 9.2 | 1.5 | 11.9 | 13.8 | 0.31 | 1.9 | 28.4 | 33.3 | 1810 | 0.393 | 55 | 30 |

| THREE CORES | ||||||||||||

| 1.5 | 1.5 | 0.8 | 3.3 | 3.8 | 0.16 | 1.4 | 10.0 | 11.7 | 205 | 13.7 | 150 | 75 |

| 2.5 | 1.95 | 0.8 | 3.7 | 4.2 | 0.16 | 1.4 | 10.9 | 12.8 | 261 | 8.21 | 130 | 65 |

| 4 | 2.5 | 0.8 | 4.2 | 4.9 | 0.21 | 1.4 | 12.2 | 14.4 | 349 | 5.09 | 110 | 55 |

| 6 | 3.0 | 0.9 | 4.9 | 5.7 | 0.21 | 1.4 | 13.8 | 16.3 | 457 | 3.39 | 90 | 45 |

| 10 | 3.9 | 1.1 | 6.1 | 7.1 | 0.26 | 1.5 | 16.9 | 19.9 | 704 | 1.95 | 85 | 45 |

| 16 | 5.0 | 1.1 | 7.5 | 8.8 | 0.26 | 1.6 | 19.3 | 22.6 | 960 | 1.24 | 70 | 35 |

| 25 | 6.4 | 1.3 | 8.9 | 10.3 | 0.26 | 1.7 | 23.1 | 27.1 | 1400 | 0.795 | 65 | 35 |

| 35 | 7.7 | 1.3 | 10.5 | 11.8 | 0.31 | 1.8 | 26.2 | 30.8 | 1827 | 0.565 | 60 | 30 |

| 50 | 9.2 | 1.5 | 11.9 | 13.8 | 0.31 | 2.0 | 30.5 | 35.7 | 2513 | 0.393 | 55 | 30 |

| FOUR CORES | ||||||||||||

| 1.5 | 1.5 | 0.8 | 3.3 | 3.8 | 0.16 | 1.4 | 10.7 | 12.6 | 248 | 13.7 | 150 | 75 |

| 2.5 | 1.95 | 0.8 | 3.7 | 4.2 | 0.21 | 1.4 | 12.0 | 14.2 | 335 | 8.21 | 130 | 65 |

| 4 | 2.5 | 0.8 | 4.2 | 4.9 | 0.21 | 1.4 | 13.3 | 15.6 | 430 | 5.09 | 110 | 55 |

| 6 | 3.0 | 0.9 | 4.9 | 5.7 | 0.21 | 1.4 | 15.1 | 17.7 | 570 | 3.39 | 90 | 45 |

| 10 | 3.9 | 1.1 | 6.1 | 7.1 | 0.26 | 1.6 | 18.6 | 21.9 | 896 | 1.95 | 85 | 45 |

| 16 | 5.0 | 1.1 | 7.5 | 8.8 | 0.26 | 1.7 | 21.3 | 24.9 | 1200 | 1.24 | 70 | 35 |

| 25 | 6.4 | 1.3 | 8.9 | 10.3 | 0.31 | 1.8 | 25.8 | 30.2 | 1815 | 0.795 | 65 | 35 |

| 3X35+25 | 7.7/6.4 | 1.3/1.3 | 10.5/8.9 | 11.8/10.3 | 0.31 | 1.9 | 30.2 | 35.4 | 2200 | 0.565/0.795 | 60 | 30 |

| 3X50+25 | 9.2/6.4 | 1.5/1.3 | 11.9/8.9 | 13.8/10.3 | 0.31 | 2.1 | 35.1 | 41.1 | 2600 | 0.393/0.795 | 55 | 30 |

(a)= For information,indicative only